Get your savings calculated today

Now we can answer a question which interested customers have long asked, namely:

You keep saying that we save a lot of time and get better quality at the same time, it is very fine, but

how much can you really save by using WelcroSoft MSD??, can we get figures on the table?

We have heard what you say, so now we have analyzed 5 years of usage and history data, and we dare call it the “Big Data”, for there were over 350,000 items to work through!

The result of the analysis was scary – for us – it turned out to be a quite unreasonable good businesscase for our customers, so it is not inconceivable that our apparently too low prices will be adjusted a bit in the near future:-),

so dear new customers:

Now could the right time, if you want the current unreasonable good price!

Another result is that we now can offer, in advance, to calculate the LEAN portion of your savings, held up against a corresponding manual handling, using only three numbers:

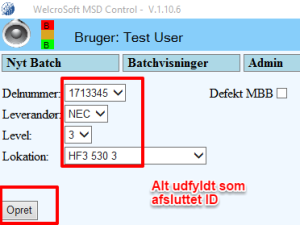

- Annual number of MSD Batches (reels, trays, etc.)

- Number of production lines

- Operator hourly rate,

When we emphasize LEAN saving, it is because only the saving of time used in the daily work,

However, only this saving can actually, in some cases, cover the investment, several times!

Almost as a bonus, on top of everything else, you will get this: the value of:

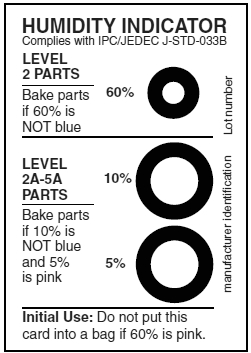

- No errors at customers due to wrong MSD handling

- No production error with MSD cause

- Production 100% according to the IPC standard

- An absolute minimum of baking

- Full overview of all MSD components

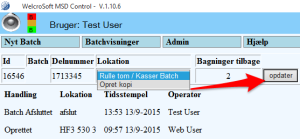

- Full history, with a single click, you will get access to everything that happened to each Batch

Get your savings calculated today